Water menace into paper gold. This transformation sounds impossible, but two young men from Assam made it real. Rupankar Bhattacharya and Aniket Dhar turned a destructive water plant into a thriving paper business. Rupankar Bhattacharya stood by the water’s edge with his camera ready. He had just rescued a python from someone’s home in Guwahati and was about to release it back into the wild. As a snake rescuer working with his mentors, Dr Jayant and Dr Madhumita Das, he had done this dozens of times before. But today he wanted to capture that perfect moment when the python would slide gracefully into the water. His finger was on the shutter button. The snake began moving toward the water. Just then, a thick blanket of green plants came floating in and covered everything. The beautiful scene he wanted to photograph was utterly ruined.

Rupankar felt frustrated looking at this mass of water hyacinth. This plant had been a menace across Assam’s rivers and lakes for years. It grew so fast that it blocked boats, choked waterways, and created problems for fishermen. Local people called it a green disaster. Later that evening, Rupankar shared his frustration with his mentors. They began discussing how this plant seemed to be everywhere, and nobody knew what to do with it. That casual conversation planted a seed in his mind. What if this troublesome plant could actually be helpful for something? He discussed the idea with his friend Aniket Dhar. Together, they began exploring whether water hyacinth could be turned into something valuable. Neither had business experience nor knew anything about manufacturing. They just had curiosity and a willingness to experiment.

The Green Menace Choking Assam’s Waterways

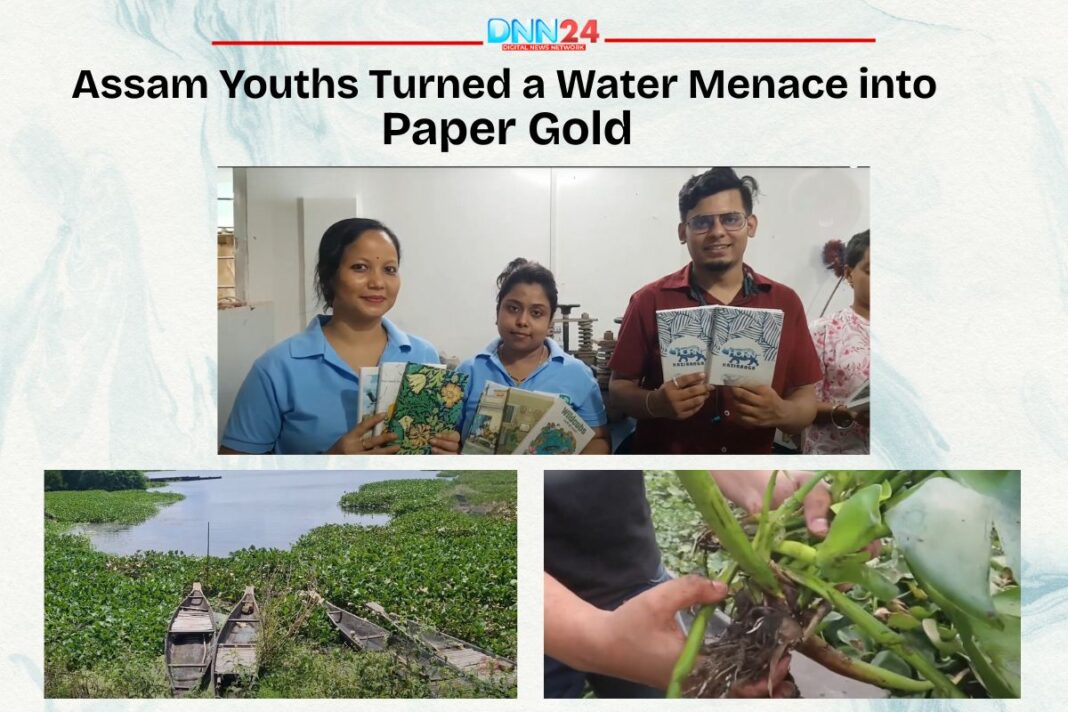

Water hyacinth has been strangling Assam’s water bodies for decades. This plant originally came from South America but found perfect growing conditions in Assam’s warm waters. It reproduces at an incredible speed. One plant can create thousands of new plants within just a few months. The impact on local communities has been devastating. Fishermen cannot move their boats through the thick mats of plants covering the water’s surface. The hyacinth blocks sunlight from reaching below, killing underwater plants and reducing oxygen levels. Fish populations have declined in many areas. During the monsoons, these floating plants block drainage channels, contributing to flooding. Authorities tried everything to control it.

They sent workers to remove the plants manually, but they grew back within weeks. Chemical sprays killed fish and harmed the environment. Mechanical harvesting is too costly and requires frequent repetition. The removed plants just rotted on the banks, creating more pollution. People living near water had accepted this as an unavoidable problem. They saw no solution in sight. But Rupankar and Aniket started researching the plant’s properties. They discovered that water hyacinth contains cellulose fibres, hemicellulose, and starch. These are precisely the components needed for making paper. The plant everyone considered worthless might actually have real value. This discovery changed everything.

Ancient Chinese Wisdom Meets Modern Assamese Innovation

While researching papermaking, Rupankar and Aniket learned something fascinating. Approximately 2,000 years ago, Chinese artisans were producing paper without the aid of modern machines or industrial chemicals. They used plant fibres, water, and simple hand tools to create durable paper that lasted for centuries. This historical fact gave them immense confidence. If ancient people could make paper using basic methods, surely they could do it with water hyacinth, given modern understanding. They started experimenting in a small workspace. The first attempts were complete failures. The pulp would not stick together properly. Sheets would tear at the slightest touch. Sometimes the mixture would be too watery, and at other times, too thick.

The drying process went wrong repeatedly. They learned through trial and error that moisture content was critical at every stage. Temperature and humidity had a significant impact on the final product. The monsoon season made everything harder because nothing dried thoroughly in the damp air. But they documented every failure and adjusted their approach each time. They were creating their own manual for working with water hyacinth. Slowly, pattern by pattern, they began to understand the plant’s behaviour. They determined the optimal time to harvest it, the duration of drying, and the processing techniques that yielded the strongest fibres. After months of failed experiments, they finally produced their first decent sheet of paper. It was rough around the edges and not perfect, but it proved their idea could work. That single sheet represented countless hours of effort and learning. It gave them the push they needed to keep going and refine their process further.

How a Troublesome Weed Becomes Beautiful Paper

The production process they developed starts with collecting water hyacinth from local rivers and lakes. Workers gather the plants during suitable seasons and transport them to drying areas. The plants are spread out in open spaces where sunlight can reach them. Summer months are ideal because the heat removes moisture quickly. The rainy season requires covered areas and takes much longer. Once completely dried, the water hyacinth goes into a special machine that Rupankar and Aniket designed themselves. They collaborated with local fabricators to construct it according to their exact specifications. This machine processes the dried plant material with water until it breaks down into a smooth, pulpy substance. Achieving the correct pulp consistency is crucial for producing high-quality paper.

The pulp then goes through traditional handmade papermaking methods. Workers pour the pulp onto frames covered with fine mesh screens. Water drains through the mesh, leaving a mat of fibres behind. These frames are carefully moved to the drying area. Natural sunlight produces the best results, giving the paper an attractive natural colour and interesting texture. The drying facility can produce around 80 sheets per hour when operating at full capacity. Each sheet must be handled with care during drying to prevent wrinkles or tears. After complete drying, the paper is ready to be used as is or converted into finished products, such as notebooks, diaries, greeting cards, and calendars. The entire process requires patience, skill, and attention to detail at every step.

From Water Menace to Community Livelihood

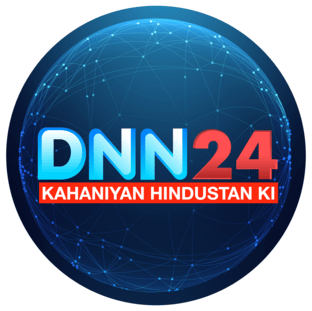

Kumbhi Kagaz became more than just a papermaking business. Rupankar and Aniket realised they could provide meaningful employment to people in their community. They began hiring residents and training them in different aspects of production. Today, the operation employs between 20 and 25 people regularly. Women and young men work in various roles across the production chain. Some collect water hyacinth from water bodies, which actually helps clean those areas. Others manage the drying yards and operate the pulping machines. A skilled team handles the delicate papermaking process, converting finished paper into a wide range of products. These jobs provide a steady income to families who previously struggled with irregular work. Many workers have developed real expertise in handmade paper production. They can judge pulp quality by touch and instinctively know when paper has dried sufficiently. This traditional knowledge is being kept alive through their work.

The social impact goes beyond wages. People in the community take genuine pride in this work. They are part of something that solves an environmental problem while creating beautiful products. When Prime Minister Narendra Modi mentioned Kumbhi Kagaz in his Mann Ki Baat program, the entire community felt recognised. National campaigns, such as Swachh Bharat Abhiyan and Zero Waste Mission, have praised this initiative as a model for sustainable entrepreneurship. Each product made from Kumbhi Kagaz tells a story of innovation, community empowerment, and environmental responsibility. What started as a moment of frustration during a python rescue has transformed into a thriving social enterprise that changes lives every single day.

Also Read: Abdul Khaliq Reshi and Kashmir’s Grape Paradise: Sweet Legacy of Repora

You can connect with DNN24 on Facebook, Twitter, and Instagram and subscribe to our YouTube channel.